Aluminum alloys are highly prized in the machining world for their superior machinability and optimal strength-to-weight ratio. As a ductile, tough, and lightweight metal, aluminum not only offers excellent machinability but also exhibits remarkable resistance to corrosion and is fully recyclable, making it an ideal choice for CNC machining. This blog post will focus on 6061 Aluminum Alloy, one of the most adaptable and frequently used aluminum alloys in CNC operations. We’ll explore its distinctive properties, advantages, and a variety of applications, highlighting why it stands out as a preferred material in the industry.

1. What is 6061 Aluminum Alloy?

6061 Aluminium alloy is a versatile aluminium alloy used in a wide range of applications and is known for its good strength-to-weight ratio and excellent corrosion resistance. It is one of the most common and versatile of the heat treatable alloys, offering a good balance of strength, corrosion resistance and weldability. Due to its fine microstructure, 6061 aluminium maintains good mechanical properties and excellent crack resistance during forming and machining.

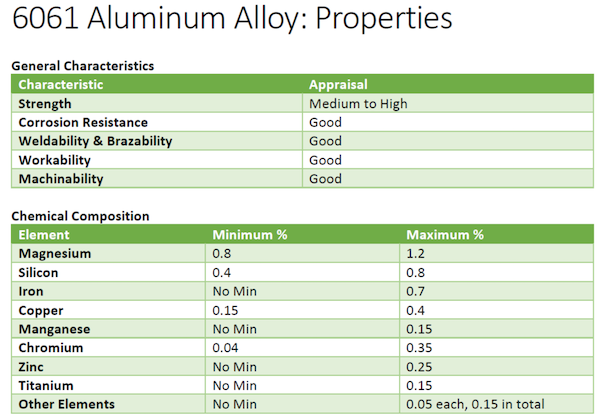

It has the following key properties:

Composition

- Aluminum (Al): 95.85 – 98.56%

- Magnesium (Mg): 0.8 – 1.2%

- Silicon (Si): 0.4 – 0.8%

- Iron (Fe): 0 – 0.7%

- Copper (Cu): 0.15 – 0.4%

- Chromium (Cr): 0.04 – 0.35%

- Other minor elements like manganese, titanium, zinc

Properties

Medium to high strength heat-treatable alloy

Good corrosion resistance

Excellent weldability and formability

Medium fatigue strength

Good machinability

Comparison with other aluminum alloys (e.g., 7075, 2024).

In comparing 6061 aluminum alloy with other popular aluminum alloys like 7075 and 2024, several key differences become apparent, each influencing the alloy’s suitability for different applications:

Strength and Ductility: 6061 aluminum alloy generally offers moderate strength combined with good ductility, making it excellent for applications requiring extensive forming or welding. In contrast, 7075 aluminum alloy is known for its high strength and is often used in applications where mechanical strength is critical, such as in aerospace components and high-performance parts. However, it is less ductile and more difficult to form and weld than 6061. Alloy 2024 is also stronger than 6061 but primarily excels in fatigue resistance, making it ideal for aircraft structural components.

Corrosion Resistance: 6061 is highly resistant to corrosion, which, coupled with its excellent weldability, makes it suitable for outdoor structural applications and in marine environments. Alloy 2024, while strong, is more prone to corrosion unless protected, limiting its use without surface treatments. Alloy 7075 also requires protective coatings to mitigate its susceptibility to corrosion.

Weldability: 6061 is one of the best aluminum alloys for welding, which is not the case with 7075 and 2024. These alloys require special techniques and are generally not recommended for welding due to their composition and the risk of weakening the structure.

Cost and Availability: 6061 is generally more available and less expensive than 7075 and 2024, partly because of its easier processing and widespread use in various industries. This availability makes it a cost-effective option for many projects, balancing performance with expense.

2. Key Properties of 6061 Aluminum Alloy

6061 aluminum alloy is renowned for its well-rounded mechanical and physical properties, making it a preferred material in various manufacturing sectors. Here’s a closer look at these properties:

Mechanical Properties

Strength: 6061 aluminum offers a good balance of strength and ductility, which can be enhanced further by heat treatment. Typically, in its T6 temper, it reaches a yield strength of about 35,000 psi and tensile strength of 42,000 psi.

Tensile Strength

6061-T4 temper: 241 MPa (35,000 psi)

6061-T6 temper: 310 MPa (45,000 psi)

Ductility:

This alloy maintains excellent ductility, allowing it to be formed into complex shapes without losing toughness, which is crucial for applications involving intricate designs or requiring high levels of deformation.

Hardness:

Brinell hardness of 95 for T6 temper

The T6 temper, which involves solution heat treatment and artificial aging, provides the maximum strength with a good combination of tensile, yield, and fatigue strengths. The T4 temper has lower strengths but better formability.

Physical Properties

Weight: Aluminum is known for its lightweight properties, and 6061 is no exception. It has a density of approximately 2.7 g/cm³, significantly less than that of steel, which helps reduce the overall weight of products, enhancing performance in applications such as automotive and aerospace where weight savings are crucial.

Thermal Conductivity: With a thermal conductivity of about 150 W/mK, 6061 aluminum effectively dissipates heat. This property is particularly valuable in applications like heat exchangers, automotive parts, and electronic housings where managing heat is vital.

Electrical Conductivity: While not as conductive as copper, 6061 aluminum is often used in electrical applications where weight and cost considerations are critical. It has approximately 40% of the conductivity of copper, making it suitable for certain electrical components, including connectors and bus bars.

Composition

– Aluminum (Al): 95.85 – 98.56%

– Magnesium (Mg): 0.8 – 1.2%

– Silicon (Si): 0.4 – 0.8%

– Iron (Fe): 0 – 0.7%

– Copper (Cu): 0.15 – 0.4%

– Chromium (Cr): 0.04 – 0.35%

– Other minor elements like manganese, titanium, zinc[1][3]

Density

– 2.7 g/cm3

Melting Point

– 585°C (1085°F)

Thermal Conductivity

– 151 – 202 W/(m·K)

Coefficient of Thermal Expansion

– 23.2 x 10^-6 /K

Specific Heat Capacity

– 897 J/(kg·K)

Electrical Resistivity

– 32.5 – 39.2 nOhm·m

3. Advantages of Using 6061 Aluminum in CNC Machining

Machinability: Why 6061 is preferred for CNC operations.

6061 aluminum alloy is widely favored for CNC machining operations due to its exceptional machinability, which presents numerous benefits for manufacturers. Here’s why 6061 is a preferred choice:

Ease of Cutting: 6061 aluminum is softer and easier to cut compared to many other aluminum alloys. This attribute reduces the wear and tear on cutting tools, extending their life and reducing maintenance costs. The ease of cutting also allows for faster machining speeds, boosting overall productivity.

Good Chip Formation: During CNC machining, 6061 aluminum tends to form small, uniform chips that do not clog the machinery. This clean chip formation enhances the efficiency of the machining process and minimizes downtime needed for cleaning and maintenance.

Excellent Surface Finish: One of the attractive features of 6061 aluminum is its ability to achieve a high-quality surface finish. When machined, it produces components with smooth surfaces that are aesthetically pleasing and require minimal post-machining finishing processes, saving time and costs.

Adaptability to Various Machining Processes: 6061 can be effectively processed using a multitude of machining operations, including milling, turning, drilling, and tapping. This versatility makes it highly adaptable for creating a wide range of parts and components.

Less Machining Time and Lower Costs: Due to its excellent machinability, machining time is reduced, which directly translates to lower production costs. This is particularly beneficial in high-volume production runs where efficiency and speed are critical.

Good Thermal Properties: 6061 dissipates heat produced during the machining process more efficiently than many other metals. This characteristic helps in maintaining the stability and integrity of the workpiece, reducing the risk of thermal distortion and enabling more precise machining.

Non-Magnetic Nature: The non-magnetic nature of 6061 aluminum is essential for industries like electronics and telecommunications, where magnetic interference can be a concern. It allows the fabrication of components that are safe and functional in sensitive applications.

Wide Range of Post-Processing Options: After machining, 6061 aluminum can be easily subjected to treatments such as anodizing, painting, and coating, which can enhance its properties or meet specific aesthetic requirements.

The combination of these properties makes 6061 aluminum a prime candidate for CNC machining, helping manufacturers achieve efficient, cost-effective, and high-quality production.

4. Applications of 6061 Aluminum in CNC Machining

6061 aluminum alloy’s versatility and favorable properties make it suitable for a wide range of CNC machining applications. Here are detailed examples of parts typically machined from 6061 aluminum, illustrating its broad utility across various industries:

Automotive Components:

6061 is extensively used in the automotive industry due to its strength and corrosion resistance. Typical parts include automotive frames, custom engine components like intake manifolds, and suspension parts. These components benefit from 6061’s durability and lightweight, contributing to overall vehicle performance and fuel efficiency.

Aerospace Fixtures:

While not the primary material for critical aerospace components, 6061 is often used for less critical parts such as brackets, fittings, and interior frames. These parts require materials that are strong yet lightweight and can withstand the environmental stresses of flight without corroding.

Consumer Electronics:

In the electronics industry, 6061 is used for enclosures, frames, and brackets in devices like smartphones, laptops, and televisions. The ability to achieve a high-quality finish through anodizing makes 6061 aluminum attractive for visible parts of consumer electronics that also require durability and light weight.

Medical Equipment:

For medical devices, 6061 is chosen for its non-toxicity and corrosion resistance. It is used in surgical tools, hospital bed frames, and wheelchair components. These applications benefit from 6061’s good strength and resistance to body fluids and cleaning chemicals.

Marine Parts:

Marine applications value 6061 for its excellent resistance to corrosion in saltwater environments. It is used in making boat hulls, gangways, and various deck components. The alloy withstands the harsh marine conditions, prolonging the lifespan of these parts.

Sporting Goods:

6061 is popular in the manufacturing of sports equipment such as bicycle frames, fishing reels, and golf club components. Its high strength-to-weight ratio is ideal for sports gear that needs to be both lightweight and capable of withstanding repetitive stress.

Construction Materials:

In construction, 6061 is used for structural components like beams, scaffolding, and architectural frameworks. These applications leverage the material’s strength and corrosion resistance to ensure safety and durability in structural applications.

These examples demonstrate the broad applicability of 6061 aluminum in CNC machining, highlighting its ability to meet the demands of diverse sectors through a combination of durability, machinability, and excellent physical properties.

5. Working with 6061 Aluminum – Best Practices

Tips for Machining 6061 Aluminum

Use Sharp Tools: Always use sharp, carbide-tipped tools for cutting 6061 aluminum. Dull tools can cause the material to smear or stick, leading to poor surface finishes and increased wear on your tooling.

Optimal Feed and Speed Rates: It’s important to use the correct feed and speed rates to prevent heat build-up which can alter the material properties. A higher feed rate with a moderate cutting speed tends to work best for 6061 to ensure clean cuts and prolong tool life.

Adequate Lubrication: Applying a suitable coolant or lubricant helps in reducing tool wear, preventing sticking, and achieving smoother cuts. This is especially critical for complex profiles or deep cuts where heat accumulation is more likely.

Climb Milling: Whenever possible, use climb milling techniques as this method helps in producing better surface finishes and imposes less stress on the machine and tooling.

Recommended Tools and Cutting Parameters

- Tool Material: Carbide tools are recommended for their hardness and resistance to wear, especially for high-volume or high-speed operations.

- Cutting Speed: Typically, a cutting speed of 500 to 800 feet per minute is effective for 6061.

- Feed Rate: Adjust the feed rate according to the depth and width of the cut but maintain it high enough to prevent the tool from rubbing and causing heat build-up.

Conclusion

6061 aluminum alloy is a standout choice for CNC machining, offering an optimal balance of machinability, strength, corrosion resistance, and aesthetic appeal. Its versatility across a range of industries—from aerospace to consumer electronics—underscores its broad applicability and value in manufacturing. By following the best practices for machining this alloy, manufacturers can ensure high-quality outcomes that meet stringent industry standards.

Interested in learning more about how 6061 aluminum can enhance your manufacturing process or need specific parts machined from this exceptional material? Visit www.rallymachining.com to explore our capabilities and get in touch with our expert team today for your CNC machining needs.

Work with RALLY for CNC Machining Parts

Request a quote for new project today! No minimum order quantity and free samples available!