Making aluminum prototypes is a crucial step in the product development process. Known for its light weight, strength, and versatility, aluminum is an excellent material for prototyping in a variety of industries. Whether you’re a seasoned manufacturer or a budding engineer, understanding the intricacies of aluminum prototypes can significantly improve the success of your project. In this guide, we’ll explore the benefits of aluminum, how to choose the right CNC service, design principles, the CNC machining process and finishing techniques to ensure your prototypes meet the highest standards.

Understanding Aluminum Prototyping

1. Benefits of Using Aluminum for Prototypes

Lightweight and Strong

Aluminum strikes an impressive balance between light weight and strength, which makes it an excellent material for creating functional prototypes. Aluminum’s light weight means that prototypes are easier to handle, transport and test in real-world scenarios.

This is particularly beneficial in industries such as aerospace and automotive, where weight reduction is critical to performance and efficiency. Despite its lightness, aluminum does not compromise on its strength in any way. It can withstand tremendous stresses and strains, ensuring that your prototypes operate reliably in a variety of conditions.

Corrosion Resistant

One of the outstanding properties of aluminum is its natural resistance to corrosion. This resistance is due to the formation of a protective oxide layer on the surface when exposed to air. This layer protects the metal from further oxidation, making aluminum an excellent choice for prototypes that need to endure harsh environments or prolonged exposure to the elements.

This durability and longevity ensures that your prototype maintains functionality and integrity throughout the testing and development phases, reducing the need for frequent replacement or maintenance.

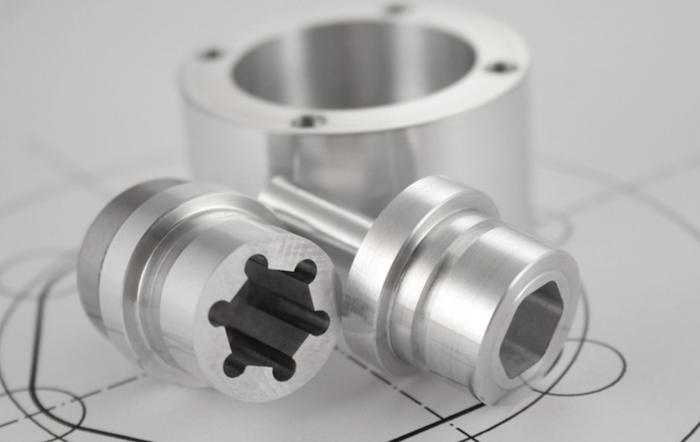

Excellent Machinability

Aluminum’s excellent machinability is another reason it is a preferred material for prototyping. It can be easily shaped into complex and precise designs using CNC machining. This ease of machining allows for greater creativity and flexibility in prototype design, enabling you to create intricate components that might be challenging to produce with other materials. The high machinability of aluminum also translates to shorter production times and lower machining costs, making the entire prototyping process more efficient and cost-effective.

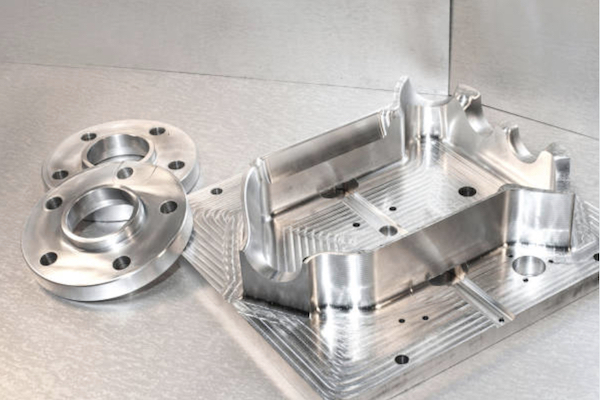

2. Applications of Aluminum Prototypes

Aerospace

In the aerospace industry, the need for materials that are high strength while remaining lightweight is critical. Aluminum prototypes fully meet these requirements, making them an integral part of aerospace engineering. Components such as fuselage structures, brackets and support elements are often prototyped in aluminum because of its ability to withstand the high stresses and strains encountered during flight.

Aluminum’s light weight helps reduce the overall weight of the aircraft, thereby improving fuel efficiency and performance. In addition, the superior machinability of aluminum allows for the creation of the aerodynamic designs required for complex geometries, ensuring that prototypes not only meet performance standards but also contribute to innovation and advances in aerospace technology.

Automotive

The automotive industry is another major beneficiary of aluminum prototyping. Aluminum is used in the development of a wide range of engine components, chassis and other structural components. Its high strength-to-weight ratio is critical to improving vehicle performance, safety and fuel efficiency.

For example, the use of aluminum in engine components helps dissipate heat efficiently while reducing the overall weight of the engine, resulting in improved performance and lower emissions. In chassis and body components, aluminum prototypes provide the necessary rigidity and impact resistance to improve vehicle safety.

Aluminum’s corrosion resistance also ensures that prototypes can withstand harsh environmental conditions, making them ideal for long-term testing and development.

Electronics

In the electronics industry, aluminum prototypes play a crucial role in the design and testing of enclosures and heat sinks. Aluminum’s excellent thermal conductivity makes it an ideal material for heat dissipation in electronic devices.

Prototype enclosures for laptops, smartphones and other electronics benefit from aluminum’s lightweight and durability, ensuring that the final product is both rugged and portable.

Aluminum heat sinks help maintain optimal operating temperatures for electronic components, improving their performance and longevity. Aluminum’s machinability allows for precise and intricate designs, which are essential for mounting complex electronic components.

Medical Devices

The medical field relies heavily on precision and reliability, making aluminum prototypes an excellent choice for the production of surgical instruments and diagnostic equipment. Aluminum’s biocompatibility and corrosion resistance ensure that medical devices remain safe and functional over time.

Prototyping surgical instruments from aluminum allows for the creation of lightweight, durable, ergonomically designed tools that are rigorously tested before final production.

Diagnostic devices such as imaging equipment and laboratory instruments benefit from the machinability of aluminum, enabling the development of detailed and accurate prototypes that are thoroughly tested and validated. This ensures that the final product meets stringent medical standards and provides reliable performance in critical medical environments.

Choosing the Right CNC Service

1. Key Factors to Consider

When selecting a CNC service for your aluminum prototype, consider the following factors:

Experience and expertise

Choose a service provider with experience in aluminum fabrication. Their expertise ensures that they can handle complex designs, anticipate potential problems, and provide solutions to improve the quality and functionality of your prototype.

Capabilities

Make sure the provider has the necessary equipment and technology to handle your project specifications. State-of-the-art machinery and the latest technology are key to producing accurate and high-quality aluminum prototypes that meet your specific requirements.

Quality Assurance

Look for services that offer quality control measures to ensure precision and accuracy. Rigorous quality assurance processes, including inspection and testing, guarantee that your prototypes are manufactured to the highest standards and are free from defects.

Turnaround time

Consider the provider’s ability to deliver within the timeframe you require. Reliable services should provide fast turnaround times without compromising on quality, enabling you to meet project deadlines and accelerate product development cycles.

2. Comparing CNC Services

It’s essential to compare different CNC services to find the best fit for your needs:

Customer Reviews

Read reviews and testimonials from previous clients to gauge satisfaction. Positive feedback and detailed reviews provide insight into the provider’s reliability, quality of work, and customer service, helping you make an informed decision based on real experiences.

Portfolio

Examine the provider’s portfolio to assess their experience with similar projects. A comprehensive portfolio showcases their capabilities, expertise in aluminum machining, and successful completion of projects like yours, ensuring they can meet your specific requirements with confidence.

Designing Your Aluminum Prototype

1. Essential Design Principles

Designing an aluminum prototype requires careful consideration of several principles:

Material Properties

Understanding aluminum’s properties, such as tensile strength and thermal conductivity, is crucial for optimizing your design. Knowledge of these properties allows you to create prototypes that not only meet structural requirements but also perform efficiently in real-world applications, ensuring durability and reliability.

Tolerance and Fit

Specifying tight tolerances and precise fits is essential to ensure the functionality of your prototype. Accurate dimensions and fits prevent issues during assembly and operation, leading to a prototype that performs seamlessly and adheres to high-quality standards, crucial for rigorous testing and development.

Weight Considerations

Leverage aluminum’s lightweight nature to enhance the overall design of your prototype. Reducing weight without compromising strength can improve performance, ease of handling, and cost-effectiveness, making your prototype more practical and efficient for both testing and eventual production.

2. CAD Software Tips for Aluminum Prototyping

Using the right CAD software can streamline the design process:

Choose Appropriate Software

Select CAD software that supports complex geometries and offers simulation tools. Advanced features like 3D modeling, stress analysis, and thermal simulations enable you to create detailed and precise aluminum prototypes, ensuring they perform optimally under various conditions. The right software can significantly enhance your design efficiency and accuracy.

Optimize for Machining

Design with CNC machining in mind, considering tool paths and cutting strategies. By incorporating machining considerations early in the design process, you can minimize material waste, reduce machining time, and ensure smoother production. This proactive approach helps in achieving higher precision and better surface finishes for your aluminum prototypes.

Collaborate with Engineers

Work closely with CNC operators and engineers to refine your design for manufacturability. Their practical insights and technical expertise can help identify potential design issues, suggest improvements, and ensure that your prototype is not only innovative but also feasible to manufacture. Effective collaboration can lead to a more efficient and successful prototyping process.

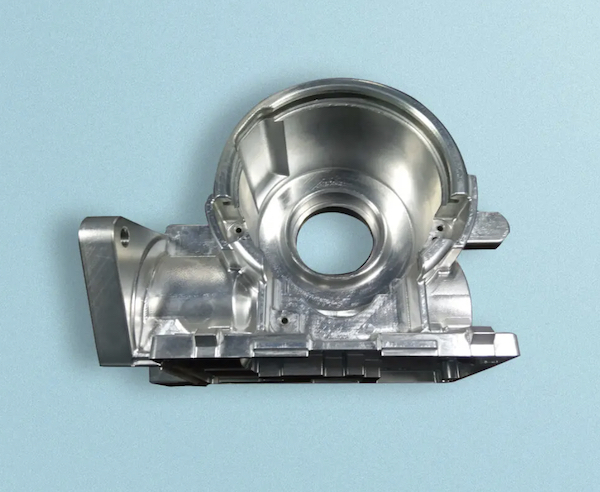

The CNC Machining Process for Aluminum

1. Step-by-Step Guide to CNC Machining

CNC machining transforms your aluminum design into a physical prototype through the following steps:

Design Translation

Convert your CAD model into CNC-compatible code. This step involves translating the intricate details of your design into machine-readable instructions, typically using CAM (Computer-Aided Manufacturing) software. This code dictates the precise movements of the CNC machine, ensuring that every cut, hole, and contour is executed according to your exact specifications.

Material Preparation

Select the appropriate aluminum grade and prepare the raw material. Choosing the right grade of aluminum is crucial as it affects the prototype’s performance, machinability, and durability. Once selected, the raw material is cut to size and cleaned to remove any contaminants, ensuring a smooth and efficient machining process.

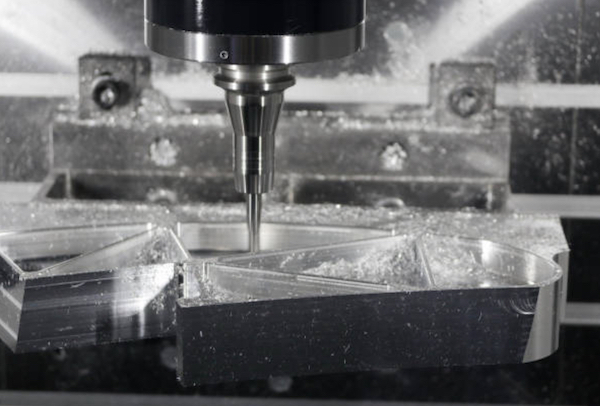

Setup

Secure the material on the CNC machine and configure the machine settings. Properly clamping the aluminum ensures stability during machining, preventing any movement that could compromise precision. Configuring the machine settings, including spindle speed, feed rate, and cutting tools, is vital to match the material properties and design requirements, setting the stage for precise and accurate machining.

Machining

The CNC machine executes the programmed tool paths to shape the material. This step is where your digital design becomes a physical reality. The CNC machine, guided by the code, meticulously cuts, drills, and shapes the aluminum according to the specified dimensions and tolerances. Continuous monitoring is essential to address any issues that may arise and to ensure the machining process is progressing as planned.

Inspection

Measure and inspect the prototype to ensure it meets design specifications. After machining, the prototype undergoes a thorough inspection process. Using precision measurement tools, such as calipers and coordinate measuring machines (CMM), every dimension and feature is checked against the design specifications. This step ensures that the prototype not only looks correct but also functions as intended, maintaining the highest standards of quality and accuracy.

By following these detailed steps, you can transform your aluminum designs into high-quality, functional prototypes, paving the way for successful product development and innovation.

2. Common Challenges and Solutions

During CNC machining, you may encounter challenges such as:

Tool Wear

Regularly check and replace cutting tools to maintain precision. Frequent inspections ensure consistent performance and prevent defects, keeping your prototype accurate and high-quality throughout the machining process.

Heat Generation

Use proper cooling techniques to prevent material distortion. Implementing effective cooling strategies, like coolant fluids or air blasts, helps maintain material integrity and dimensional accuracy, ensuring your prototype meets exact specifications.

Surface Finish

Adjust cutting parameters to achieve the desired surface finish. Fine-tuning feed rates, spindle speeds, and tool paths can enhance surface quality, resulting in smooth, professional-looking prototypes that are ready for testing and further development.

Finishing and Testing Your Prototype

1. Post-Machining Finishing Techniques

After machining, finishing processes enhance the prototype’s appearance and functionality:

Deburring

Remove sharp edges and burrs from the machined parts. Deburring is essential to ensure safety and enhance the aesthetic appeal of your aluminum prototype. This process involves carefully smoothing out any rough or jagged edges that remain after machining.

Techniques such as manual filing, abrasive blasting, or using specialized deburring tools help create clean, precise edges, improving both the look and functionality of the prototype.

Proper deburring also prevents potential issues during assembly and use, contributing to the overall quality and reliability of your product.

Polishing

Achieve a smooth, reflective surface through polishing. Polishing transforms the machined aluminum prototype into a visually appealing and professional-looking product. This process involves using various abrasives and polishing compounds to eliminate minor surface imperfections, scratches, and machining marks.

The result is a smooth, shiny surface that enhances the prototype’s appearance and can also improve its performance by reducing friction and wear. Polished surfaces are particularly important in applications where aesthetics and smooth operation are critical, such as in consumer electronics or medical devices.

Anodizing

Apply an anodic oxide finish to improve corrosion resistance and aesthetics. Anodizing not only enhances the visual appeal of your aluminum prototype by offering a range of colors and finishes but also significantly boosts its durability.

This electrochemical process creates a thick, protective oxide layer on the surface of the aluminum, making it highly resistant to corrosion, wear, and environmental factors.

Anodizing can also improve the prototype’s surface hardness and provide better adhesion for paint and adhesives. This finishing technique is ideal for prototypes that will undergo extensive testing or be exposed to harsh conditions, ensuring they remain functional and visually appealing over time.

By implementing these post-machining finishing techniques, you can elevate the quality and performance of your aluminum prototypes, ensuring they meet the highest standards and are ready for real-world application and evaluation.

2. Prototype Testing and Validation

Testing and validation are critical to ensure your prototype performs as intended:

Functional Testing

Assess the prototype’s performance in real-world conditions. Functional testing involves subjecting your aluminum prototype to the environments and stresses it will encounter during actual use. This testing phase is crucial for identifying any operational issues, performance bottlenecks, or unexpected behaviors.

By replicating real-world scenarios, you can ensure that the prototype performs as intended and meets the necessary performance standards. Functional testing provides valuable insights into the prototype’s strengths and weaknesses, allowing you to make informed adjustments and enhancements.

Dimensional Inspection

Verify that the prototype’s dimensions match the design specifications. Dimensional inspection is a meticulous process that involves measuring and comparing the prototype’s physical dimensions against the original CAD model. Using precision instruments like calipers, micrometers, and coordinate measuring machines (CMM), this inspection ensures that every aspect of the prototype is accurate and within tolerance limits.

Accurate dimensions are essential for the proper fit and function of the prototype, particularly in complex assemblies. This step guarantees that the prototype not only looks correct but also performs as expected in its intended application.

Iterative Improvements

Use feedback from testing to refine and improve the prototype design. Iterative improvements are an ongoing process of refinement and enhancement based on the results of functional testing and dimensional inspection. By analyzing feedback and performance data, you can identify areas for improvement and make necessary design adjustments.

This iterative approach ensures that the prototype evolves with each testing cycle, becoming more robust, reliable, and closer to the final product. Continuous iteration helps in addressing potential issues early, reducing the risk of costly changes later in the development process, and ultimately leading to a higher quality and more successful product.

Contact RALLY for Custom Aluminum Prototype

Ready to have your aluminum prototype transformed into reality? Contact RALLY for expert custom aluminum prototyping services. Our experienced team ensures precision, quality, and fast turnaround times for all your prototyping needs. Contact us today for a consultation and free quote!

Work with RALLY for CNC Machining Parts

Request a quote for new project today! No minimum order quantity and free samples available!