Precision CNC Milling Services

Custom Precision Milling for Complex Projects – Delivered On Time, Every Time.

RALLY's CNC Milling Services

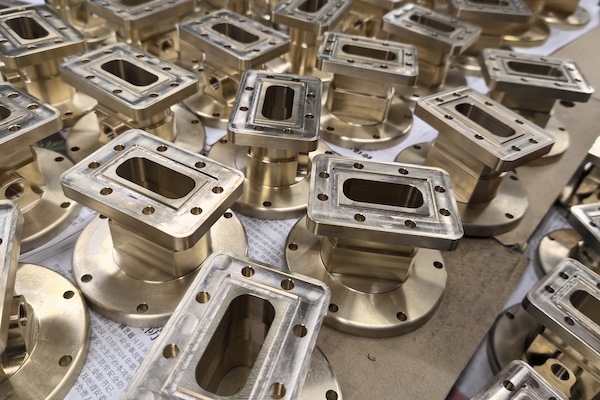

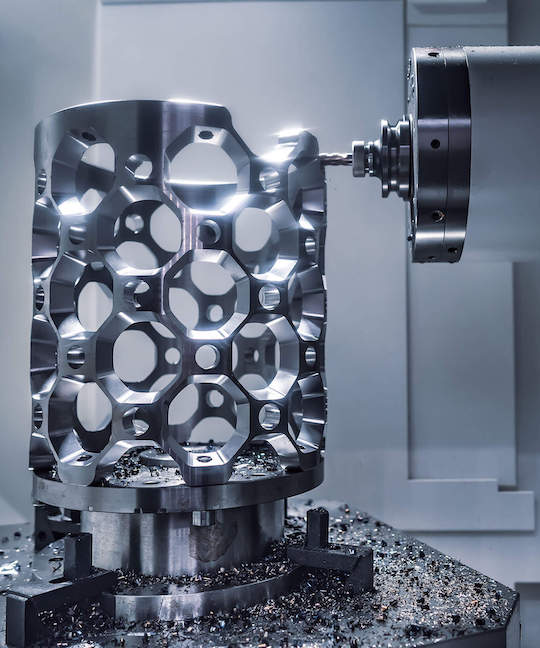

RALLY offers a comprehensive range of CNC milling services, capable of machining a variety of materials to meet the diverse needs of different industries. We excel in working with aluminum, stainless steel, brass, and various types of plastics. Whether you require lightweight, high-strength metal components or engineered plastics with specialized properties, we provide precise machining services tailored to your specifications. Our CNC milling equipment is highly versatile, allowing us to handle projects of varying complexity—from simple 2D cutting to intricate 3D contour milling—with efficiency and precision.

Our expertise in high-precision part manufacturing is a key advantage. At RALLY, we utilize state-of-the-art CNC milling technology to ensure that each part meets exceptionally tight tolerance requirements. We have the capability to machine components with micron-level precision and achieve superior surface finishes, making us an ideal partner for industries where quality and detail are paramount, such as aerospace, medical devices, and high-end manufacturing. Our experienced team of engineers and skilled operators work closely together to ensure that every project is produced to the client’s exacting standards.

Our Advantages

Precision and Quality Control:

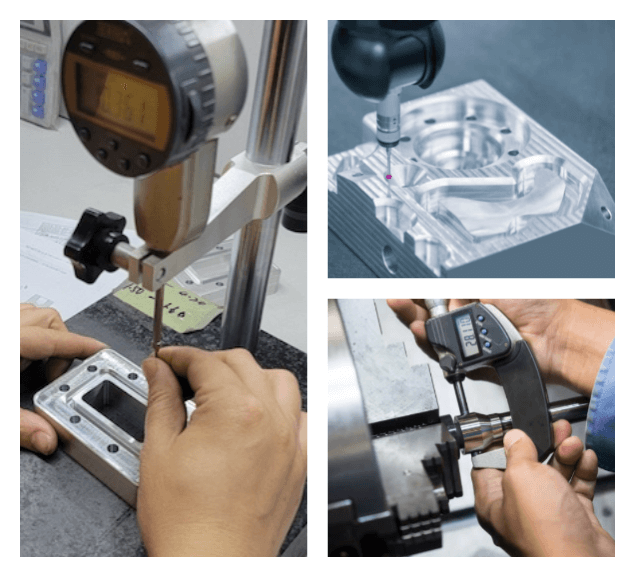

At RALLY, precision is at the core of everything we do. We ensure that every CNC milled part meets exacting standards of accuracy and consistency. Our advanced machining centers are equipped with cutting-edge technology capable of achieving tight tolerances down to the micron level. To maintain these high standards, we employ state-of-the-art inspection equipment, including coordinate measuring machines (CMMs) and laser scanners, which allow us to rigorously monitor and verify the quality of each part throughout the production process.

Customized Solutions:

At RALLY, we take pride in offering fully customized solutions tailored to our clients’ specific needs. Whether you’re dealing with complex geometries, specialized materials, or unique application requirements, RALLY’s expertise in CNC milling allows us to deliver bespoke solutions that meet your exact specifications, ensuring that you receive components perfectly suited to your project.

Case Studies

1. Aerospace Industry – High-Precision Engine Components Manufacturing:

RALLY partnered with a leading aerospace company to produce critical high-precision components for their jet engines. The client required extremely tight tolerances to ensure the safety and performance of the engines under extreme conditions. RALLY utilized advanced CNC milling technology and rigorous quality control processes to successfully manufacture parts that met the client’s exacting standards, ultimately enhancing the reliability and efficiency of the engines.

2. Medical Devices Industry – Custom Implant Manufacturing:

In the medical devices sector, RALLY collaborated with a prominent medical equipment manufacturer to develop and produce custom surgical implants. Given the stringent requirements for material selection and machining precision in medical applications, RALLY used medical-grade stainless steel and titanium alloys. Through precise milling processes, we ensured that each implant was perfectly shaped with flawless surface finishes. The final products not only passed rigorous medical certifications but also performed exceptionally well in clinical settings.

3. Automotive Industry – Complex Vehicle Body Structure Manufacturing:

RALLY worked with a major automotive manufacturer to produce high-strength, lightweight body structure components. These parts needed to maximize weight reduction while maintaining structural integrity to improve fuel efficiency and safety. By precisely milling aluminum alloys, RALLY successfully delivered body structure components that met the client’s specifications and passed a series of stringent crash tests and durability assessments.

Get a Quick Quote for Free Samples

Request a quick quote now and receive free samples of our precision CNC machining parts tailored to your specifications!

FAQ for CNC Milling Services

1. What materials can RALLY machine?

2. What tolerances can your CNC milling services achieve?

3. Can your production capacity meet my order volume?

4. Can you provide free samples?

5. What is your typical delivery time?

Get in Touch

Ready to get started? Contact us today for a free quote!

Metal Material

Aluminum, Brass, Stainless Steel, Carbon Steel, Copper, Titanium, etc.

Plastic Material

Acetal (Delrin), PTFE (Teflon), Acrylic (PMMA), PEEK, Nylon, ABS, PC, PP, POM, HDPE, PVC.

Surface Finishing

Anodizing, Powder Coating, Plating, Passivation, Bead Basting, Polishing, etc.

Inquiry Form

Let’s Start A New Project Today, Get Free Samples!

All You Need To Know About CNC Milling Services

Table of Contents

What are the advantages of CNC machined parts?

CNC machining of parts has many advantages, which makes it a very popular method of machining in modern manufacturing. Here are some of the main advantages:

High Accuracy

CNC machining is able to cut accurately at the micron level, ensuring that parts meet tight tolerances. This high level of precision makes CNC machining suitable for industries such as aerospace, medical and automotive, enabling the manufacture of parts with complex shapes and details.

Efficient production

CNC machining is highly automated and capable of working 24/7, which significantly increases productivity. CNC machining allows parts to be produced faster and with shorter lead times than traditional machining methods.

Flexibility and Complex Geometry Machining

CNC machines can handle complex designs and geometries, and support multiple axes simultaneously, making it easy to respond to complex machining requirements. This flexibility allows manufacturers to respond faster to design changes.

Material Versatility

CNC machining is suitable for a wide range of materials, including metals (e.g. aluminum, steel, stainless steel, copper, etc.) and plastics (e.g. ABS, nylon, PTFE, etc.), to meet the needs of different industries and applications.

What is the process of CNC machining?

1. Design Stage

- Product Design: Create detailed 3D models or 2D drawings using computer-aided design (CAD) software. These designs include all necessary dimensions, geometries, and tolerances.

2. Programming Stage

- CNC Programming: Convert the CAD model into a CNC program (G-code) using computer-aided manufacturing (CAM) software to generate machining paths. The program includes tool paths, feed rates, cutting speeds, and other machining parameters.

3. Preparation Stage

Material Preparation: Select and prepare the raw materials needed for machining, cutting them to the appropriate size based on the design drawings.

Machine Setup: Install and adjust the necessary tools and fixtures on the CNC machine to ensure it is in optimal working condition.

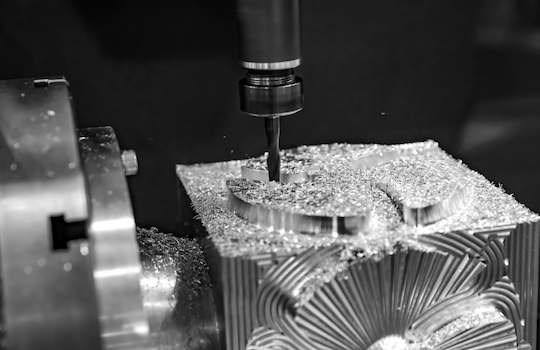

4. Machining Stage

First Article Inspection: Perform a trial cut to verify the program’s accuracy and the machine’s setup, ensuring the part meets design requirements.

Batch Production: Once the first article passes inspection, begin batch production. The machine automatically executes the CNC program to perform cutting, milling, drilling, and other operations on the material.

5. Quality Control

Process Monitoring: Continuously monitor machine operations and machining precision during the process, adjusting parameters to ensure quality.

In-Process Inspection: Conduct intermediate inspections on partially completed parts to check dimensions and tolerances.

6. Post-Processing Stage

Deburring and Cleaning: After machining, deburr and clean the parts to remove any burrs and impurities generated during the process.

Surface Treatment: Perform surface treatments such as polishing, painting, or plating as required by the design to enhance the part’s appearance and performance.

7. Final Inspection

- Quality Check: Use precision measuring tools to thoroughly inspect the final product, ensuring all dimensions and tolerances meet design specifications.

How to choose the right material for CNC machining?

There are several key factors to consider when selecting materials for CNC machining.

Strength and hardness:

Choose materials with sufficient strength and hardness to withstand the stresses and wear of the machining process. Aluminium alloys, stainless steel and titanium are commonly used.

Corrosion resistance:

If the end product is to be used in a corrosive environment, it is important to select a material that is corrosion resistant, such as stainless steel.

Thermal conductivity:

The thermal conductivity of a material affects the distribution of heat during the cutting process. Aluminium alloys have good thermal conductivity.

Machinability Assessment:

Evaluate the cutting performance of the material in CNC machining. Factors such as hardness, toughness, and ductility can affect the difficulty of machining. For example, aluminum is easy to machine, while titanium and stainless steel may require harder tools and longer machining times.

Surface Quality:

Some materials are easier to achieve a high-quality surface finish after machining, which can reduce the need for subsequent polishing or surface treatments. For instance, aluminum often results in a smoother finish, whereas harder materials might require additional finishing steps.

Material Cost:

Select materials that fit within your budget. Consider the cumulative effect of material costs in large-scale production. Low-cost materials (such as certain plastics) may be more suitable in specific conditions.

Machining Cost:

The difficulty of machining a material affects the overall machining cost. More challenging materials may require specialized equipment or tools, which can increase production costs.

Prototyping:

Before full-scale production, create a small number of samples or prototypes using the selected material to assess its performance in actual machining and application scenarios.

Performance Validation:

Test the prototype for mechanical properties, chemical stability, and machining effects to ensure the material meets design and application requirements.

How to ensure the quality of CNC machined parts?

Ensuring the quality of CNC machined parts is a multifaceted process that involves all aspects of the process, from design to production. Here are some key strategies and best practices to ensure high quality CNC machined parts:

1. Use High-Quality Raw Materials

- Material Selection: Ensure that high-quality raw materials meeting specifications and performance requirements are used.

- Supplier Evaluation: Choose reliable material suppliers and regularly audit their product quality and delivery capabilities.

2. Advanced Equipment and Technology

- Equipment Maintenance: Regularly maintain and calibrate CNC machines to ensure they are in optimal working condition.

- Technology Upgrades: Utilize the latest machining technologies and software to improve precision and efficiency.

3. Precise Process Control

- Programming Accuracy: Ensure the accuracy of CNC programs to avoid machining deviations due to programming errors.

- Process Monitoring: Monitor key parameters in real-time during machining, such as cutting speed, feed rate, and tool wear, to ensure process stability.

4. Rigorous Quality Inspection

- First Article Inspection: Conduct detailed inspections on the first piece produced in each batch to verify the correctness of machining parameters and process settings.

- In-Process Inspection: Regularly inspect parts during machining to ensure continuous compliance with quality standards.

- Final Inspection: Use precision measurement tools (such as coordinate measuring machines) to thoroughly inspect the final product, ensuring its dimensions and tolerances meet requirements.

5. Training and Management

- Employee Training: Enhance the skills of operators and quality inspectors to ensure they can identify and correct machining issues.

- Quality Management System: Establish and maintain a quality management system that complies with international standards such as ISO to systematically manage and improve quality control processes.

By implementing these steps, you can significantly enhance the quality of CNC machined parts, ensuring that the products meet customer expectations and market demands.

How is the Lead Time for CNC Machining Determined?

The lead time for CNC machining is influenced by several key factors:

Complexity of the Design: Intricate designs with tight tolerances or multi-step processes typically require more time to machine.

Material Availability: The availability of the chosen material can impact how quickly the project can begin. If special or rare materials are required, lead time may increase.

Production Volume: Larger batch sizes or mass production runs generally take longer compared to prototyping or small batch orders.

Current Production Schedule: The supplier’s existing workload and production capacity also affect the turnaround time.

Post-Processing Requirements: If additional processes like heat treatment, surface finishing, or assembly are needed, these will add to the total lead time.

What is the Tolerance Range for CNC Machined Parts?

The tolerance range for CNC machined parts can vary depending on several factors:

Material Type:

Different materials, such as metals or plastics, have varying machinability, which can affect the achievable tolerance.

Part Complexity:

More complex designs with intricate features may require tighter tolerances, which can be more challenging to achieve.

Machine Capability:

The precision of the CNC machine itself plays a critical role. High-precision machines can achieve tighter tolerances, often within ±0.001 inches (±0.025 mm) or better.

Application Requirements:

The specific needs of the application, such as those in aerospace or medical industries, might demand stricter tolerances.

Post-Processing:

Additional processes like heat treatment or surface finishing can affect the final tolerance, so these must be factored in during the planning stage.

By understanding these factors, you can better determine the appropriate tolerance for your CNC machined parts and ensure they meet the necessary specifications.

How to Handle Potential Issues During CNC Machining?

Addressing issues during CNC machining is crucial to ensure the quality and precision of the final parts. Here’s how potential problems can be managed:

Regular Monitoring and Inspection:

Continuous monitoring during machining and regular inspections help identify issues early, such as tool wear or machine misalignment, allowing for quick adjustments.

Material Selection:

Choosing the right material for the part is essential. Improper material selection can lead to machining difficulties, such as excessive tool wear or part deformation. Working closely with suppliers can help ensure the correct material is used.

Tooling and Fixture Optimization:

Using the appropriate tools and fixtures can prevent problems like part movement, vibration, or poor surface finish. Ensuring tools are sharp and well-maintained is also key.

Programming Accuracy:

CNC programming errors can lead to dimensional inaccuracies or surface defects. Careful review and simulation of CNC programs before actual machining can help avoid such issues.

Addressing Heat and Stress:

Excessive heat generation during machining can cause material distortion or warping. Managing cutting speeds, feeds, and cooling techniques is important to mitigate these effects.

By implementing these strategies, potential issues during CNC machining can be effectively managed, ensuring high-quality results and minimizing production delays.

Work with RALLY for CNC Turning Parts

Request a quote for new project today! No minimum order quantity and free samples available!