In modern manufacturing, CNC machining prototype services are crucial for transforming innovative designs into tangible products with high precision. The demand for high-precision prototypes in Georgia is rising, driven by industries such as aerospace, automotive, and medical devices. As this demand grows, businesses seek reliable partners for their CNC machining needs. RALLY stands out as a trusted provider, offering top-tier CNC machining prototype services.

1. Importance of Precision in Prototyping

1.1 The Role of Precision in Creating High-Quality Prototypes

Precision in prototyping is the cornerstone of creating high-quality, functional models. When developing a prototype, even the smallest deviations can lead to significant flaws in the final product. High precision ensures that each component fits perfectly, functions as intended, and meets the exact specifications required. This level of detail is crucial in industries where accuracy can mean the difference between success and failure, such as aerospace, automotive, and medical device manufacturing.

By utilizing advanced CNC machining techniques, companies can achieve the utmost precision, ensuring that their prototypes are not only accurate but also reliable and ready for mass production.

1.2 How Precision Impacts the Final Product Quality and Functionality

The precision used in prototyping directly influences the quality and functionality of the final product. Accurate prototypes serve as a vital step in detecting and correcting design flaws before full-scale production. This preemptive approach helps prevent costly mistakes and reworks, ensuring a smoother production process.

Furthermore, precision in the prototyping phase guarantees that the end product will meet all performance and safety standards. By investing in precise prototyping, businesses can enhance product durability, improve performance, and ensure customer satisfaction.

2. CNC Milling Services Near Me Georgia

2.1 Advanced CNC Milling Capabilities

Overview of the Advanced Milling Techniques Used by RALLY

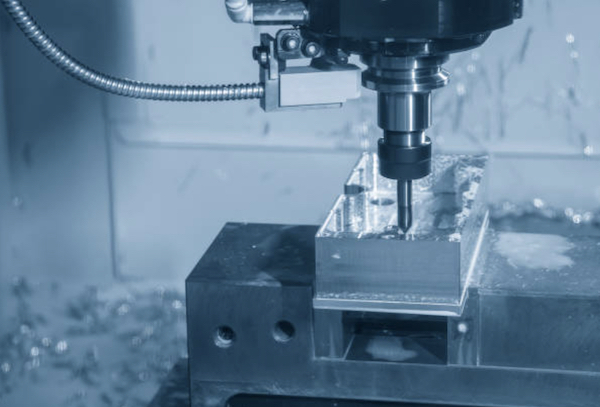

RALLY stands at the forefront of CNC milling technology, utilizing state-of-the-art techniques to achieve unparalleled precision and efficiency. Our advanced milling capabilities include multi-axis machining, high-speed cutting, and precision micro-milling.

Multi-axis machining allows us to create complex geometries and intricate designs that are impossible with traditional methods.

High-speed cutting ensures faster production times without compromising on accuracy, while precision micro-milling enables the manufacture of extremely detailed components with microscopic features.

By leveraging these cutting-edge techniques, RALLY consistently delivers high-quality prototypes that meet the stringent requirements of various industries, from aerospace to medical devices.

Examples of Complex Parts and Components Manufactured

At RALLY, our expertise in advanced CNC milling techniques is demonstrated through the diverse range of complex parts and components we manufacture.

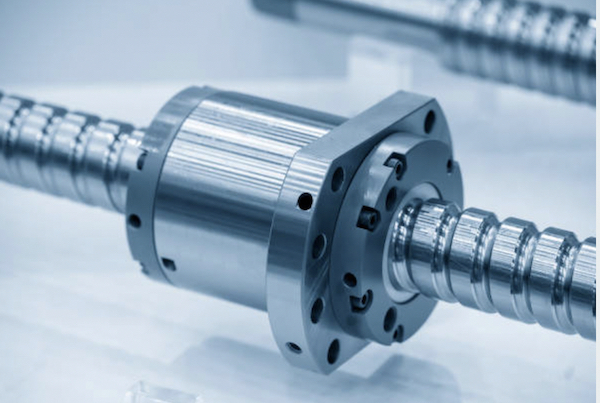

For instance, we produce intricate aerospace components that require tight tolerances and exceptional durability. Our capabilities extend to creating custom medical device prototypes, such as surgical instruments and implants, which demand the highest precision and biocompatibility.

Additionally, we manufacture high-performance automotive parts, including engine components and custom gear systems, designed to withstand extreme conditions. Each of these examples showcases our ability to handle challenging projects and deliver superior results, making RALLY a trusted partner in precision CNC machining.

3. Top Machining Company Near Me Georgia

3.1 RALLY’s Expertise and Experience

Background of RALLY and Its Journey in CNC Machining

RALLY has built a stellar reputation in the CNC machining industry, driven by decades of experience and a commitment to excellence. Founded with a vision to provide precision machining solutions, RALLY has grown into a leading CNC machining company in Georgia, serving a diverse clientele across various sectors.

Our journey began with a small team of dedicated engineers who were passionate about leveraging cutting-edge technology to solve complex manufacturing challenges. Over the years, we have continuously invested in the latest machinery and training for our workforce, ensuring that we stay ahead of industry advancements and maintain our position as a leader in CNC machining.

3.2 Customer Testimonials and Case Studies

Real-Life Success Stories and Satisfied Customer Reviews

Our commitment to quality and precision has earned us numerous satisfied customers who are eager to share their positive experiences. Clients consistently praise our attention to detail, quick turnaround times, and exceptional customer service.

For example, a leading aerospace company recently commended us for delivering complex components ahead of schedule, significantly accelerating their project timeline. Another client, a medical device manufacturer, highlighted how our precision machining services helped them develop a revolutionary surgical instrument that has since received widespread acclaim.

These testimonials underscore our dedication to meeting and exceeding customer expectations, reinforcing RALLY’s reputation as a trusted CNC machining partner.

Case Studies Showcasing RALLY’s Problem-Solving Capabilities

Our portfolio includes a range of case studies that illustrate RALLY’s problem-solving capabilities and innovative approach to CNC machining. One notable case involved a client from the automotive industry who faced challenges with a critical engine component.

Through collaborative efforts and advanced milling techniques, we developed a prototype that not only met their requirements but also enhanced performance and durability. Another case study features our work with an electronics company needing precision components for a new device.

Our team designed and manufactured the parts with such accuracy that it led to a successful product launch, garnering significant market attention. These case studies exemplify our ability to deliver customized solutions that drive success for our clients.

4. Leading CNC Machining Company Georgia

4.1 State-of-the-Art Equipment and Facilities

Description of the Cutting-Edge Machinery and Equipment at RALLY

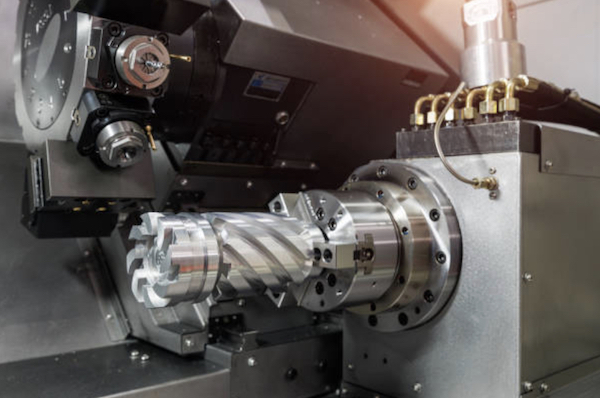

At RALLY, we pride ourselves on having one of the most advanced CNC machining facilities in Georgia. Our state-of-the-art equipment includes the latest multi-axis CNC machines, high-speed milling machines, and precision lathes, all designed to deliver the highest levels of accuracy and efficiency.

Our multi-axis machines allow for complex geometries and intricate details, while our high-speed milling machines ensure rapid production without sacrificing precision.

Additionally, our precision lathes are capable of producing highly detailed components with tight tolerances. Each piece of machinery is meticulously maintained and regularly upgraded to incorporate the latest advancements in CNC technology.

This commitment to using cutting-edge equipment enables us to tackle even the most challenging projects with ease and precision, ensuring that our clients receive the highest quality prototypes and components.

4.2 Commitment to Quality and Innovation

RALLY’s Quality Assurance Processes and Certifications

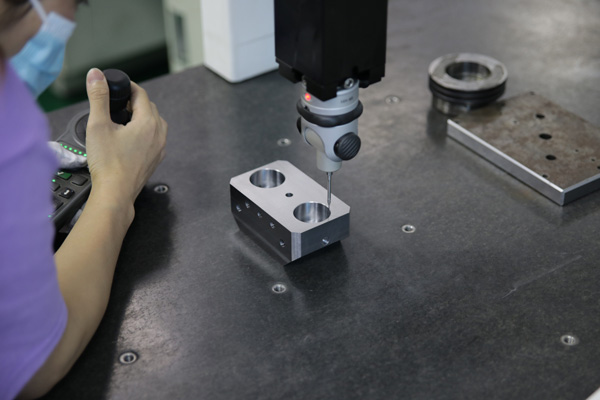

Quality and innovation are at the heart of everything we do at RALLY. Our stringent quality assurance processes are designed to ensure that every component we produce meets the highest standards of precision and reliability.

We adhere to ISO 9001 and AS9100 certifications, which require rigorous quality management practices and continuous improvement. These certifications reflect our commitment to maintaining excellence in all our operations.

Our quality assurance team employs advanced inspection techniques, including coordinate measuring machines (CMM) and optical comparators, to verify that each part meets the specified dimensions and tolerances.

Additionally, we have implemented a robust traceability system to monitor every stage of the production process, ensuring accountability and transparency. By prioritizing quality and innovation, we not only meet but exceed our clients’ expectations, delivering products that perform reliably in the most demanding applications.

Our dedication to quality assurance and our pursuit of cutting-edge technologies set RALLY apart as a leader in the CNC machining industry.

5. Prototype Machining Georgia Solutions

5.1 Customized Prototyping Services

Tailored Prototyping Solutions to Meet Specific Client Needs

At RALLY, we understand that every client has unique requirements and challenges, which is why we offer tailored prototyping solutions designed to meet specific needs. Our approach begins with a thorough consultation to understand your project’s goals, specifications, and constraints.

We then leverage our extensive expertise and advanced CNC machining capabilities to develop prototypes that precisely match your vision. Whether you need a single component or a complex assembly, we can customize our services to provide the ideal solution.

Our flexible prototyping process allows for iterative design adjustments, ensuring that the final product not only meets but exceeds your expectations. By working closely with our clients, we ensure that every prototype we deliver is a perfect fit for its intended application, providing a solid foundation for successful product development.

Examples of Custom Prototypes Developed by RALLY

RALLY has a proven track record of developing custom prototypes that address a wide range of industry needs. For instance, we recently partnered with an innovative medical device company to create a prototype for a new surgical instrument. This complex project required precise tolerances and biocompatible materials, which we achieved through our advanced CNC machining processes. The resulting prototype was not only functional but also aesthetically pleasing, helping our client secure crucial funding for further development.

In another example, we collaborated with an aerospace manufacturer to develop a prototype for a new type of lightweight, high-strength component. Utilizing our multi-axis CNC machines, we were able to produce a prototype that met all structural and performance requirements, enabling our client to move forward with testing and certification.

These examples highlight RALLY’s ability to deliver customized prototyping solutions that address the unique challenges of each project. Our dedication to precision, quality, and innovation ensures that every prototype we create is a step toward our clients’ success, making RALLY a trusted partner in the journey from concept to reality.

6. Benefits of Choosing RALLY

Choosing RALLY for your CNC machining and prototyping needs comes with numerous competitive advantages that set us apart from other providers. Firstly, our commitment to precision ensures that every component we produce meets the highest standards of accuracy, giving you confidence in the reliability and performance of your final product. Our state-of-the-art equipment, including multi-axis CNC machines and high-speed milling machines, allows us to handle even the most complex projects with ease and efficiency.

Moreover, our team of skilled professionals brings a wealth of experience and expertise to every project. This means you benefit from innovative solutions and a level of craftsmanship that is second to none. Our dedication to quality is further evidenced by our stringent quality assurance processes and adherence to ISO 9001 and AS9100 certifications, ensuring that every product we deliver is of the highest quality.

Additionally, RALLY offers flexible and tailored prototyping services to meet your specific needs. Whether you require a quick turnaround for a tight deadline or a custom solution for a complex project, we have the capability to deliver. Our customer-centric approach means we work closely with you throughout the entire process, providing regular updates and accommodating any adjustments to ensure the final product aligns perfectly with your vision.

Finally, our extensive portfolio of successful projects and satisfied clients speaks volumes about our reliability and excellence. From aerospace components to medical devices, our prototypes have helped clients across various industries achieve their goals and bring innovative products to market.

Prototype Manufacturing Near Me Georgia | RALLY

Ready to experience the precision and quality of RALLY’s CNC machining and prototyping services? Contact us today to discuss your project requirements and discover how we can help bring your ideas to life.

Work with RALLY for CNC Machining Parts

Request a quote for new project today! No minimum order quantity and free samples available!