Stainless Steel Machining

High-Precision Machining · Global Delivery · Prototype & Mass Production Support

Stainless Steel Machining CNC Precision Service

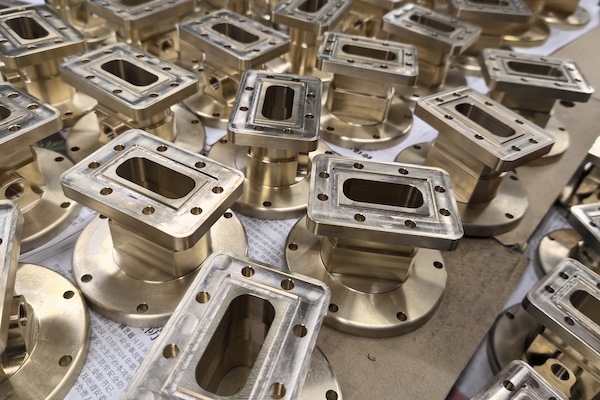

RALLY is a stainless steel machining manufacturer with years of experience, specializing in producing high-precision custom parts. We leverage advanced CNC machining technologies to deliver tailored solutions that meet our clients’ exact requirements, regardless of complexity. From simple prototypes to large-scale production, we handle projects of all sizes with equal expertise and attention to detail.

Our services span multiple industries, including medical devices, aerospace, automotive, and industrial manufacturing. Each industry we serve benefits from our ability to meet strict specifications while ensuring superior quality. Our team works closely with clients to align each project with their technical drawings and functional needs.

RALLY is trusted worldwide for its robust quality control processes, fast turnaround times, and reliable global delivery. With no minimum order quantity (MOQ) and flexible production schedules, we help our partners stay competitive in their markets.

Our Services Include:

CNC Turning and Milling:

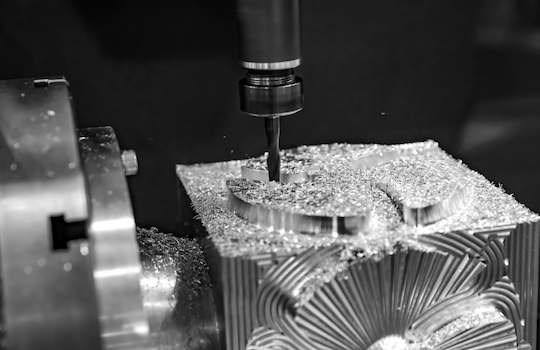

Advanced CNC machines deliver high-precision turning and milling services. Whether handling complex geometries or tight tolerances, the machining process ensures reliable and accurate results for custom stainless steel components.

Laser Cutting and Welding:

Laser cutting technology provides clean and precise cuts for intricate designs, while welding services ensure durable and seamless joints. These techniques are ideal for producing complex parts with exceptional strength and aesthetics.

Surface Treatments (Polishing, Passivation, etc.):

A variety of surface treatments are available, including polishing for smooth finishes and passivation to enhance corrosion resistance, ensuring parts meet both functional and aesthetic standards.

Prototype Development and Small Batch Production:

Support is provided from the prototyping phase through small batch production, enabling rapid iterations and ensuring the design meets expectations before scaling to mass production.

Our Advantages:

Material Selection:

Support for 304, 316, and other stainless steel grades to meet diverse needs.

Precision Machining:

Achieve tight tolerances of ±0.01mm for high-accuracy components.

Fast Delivery:

Reliable global logistics ensures timely shipping worldwide.

Quality Assurance:

ISO-certified quality control for consistent, high-standard products.

Custom Services with No MOQ:

Flexible solutions from prototypes to mass production with no minimum order quantity.

Get a Quick Quote for Free Samples

Request a quick quote now and receive free samples of our precision CNC machining parts tailored to your specifications!

FAQ for Stainless Steel Machining

1. What stainless steel grades can RALLY process?

2. What is the machining precision for stainless steel parts?

3. Do you support small-batch or prototype production?

4. Are surface treatments available for machined parts?

5. What is RALLY’s typical production lead time?

6. How do you ensure product quality?

7. Can you ship globally?

Get in Touch

Ready to get started? Contact us today for a free quote!

Metal Material

Aluminum, Brass, Stainless Steel, Carbon Steel, Copper, Titanium, etc.

Plastic Material

Acetal (Delrin), PTFE (Teflon), Acrylic (PMMA), PEEK, Nylon, ABS, PC, PP, POM, HDPE, PVC.

Surface Finishing

Anodizing, Powder Coating, Plating, Passivation, Bead Basting, Polishing, etc.

Inquiry Form

Let’s Start A New Project Today, Get Free Samples!

All You Need To Know About Stainless Steel Machining

Table of Contents

Common Types of Stainless Steel Used in CNC Machining

CNC machining frequently utilizes several types of stainless steel, each suited for specific applications. 304 stainless steel is known for its excellent corrosion resistance, making it ideal for food processing and medical devices.

316 stainless steel offers enhanced resistance to chemicals and marine environments, commonly used in aerospace and marine parts.

17-4 PH stainless steel is a precipitation-hardened alloy, providing high strength and hardness for aerospace components.

430 stainless steel is a cost-effective option with good corrosion resistance, often used in automotive trims and appliances. Each type offers unique properties, helping manufacturers meet the needs of diverse industries.

Surface Treatment Processes for Stainless Steel Parts

Surface treatments enhance the performance, appearance, and durability of stainless steel parts. Passivation is a chemical process that removes contaminants and improves corrosion resistance by forming a protective oxide layer. Electropolishing smooths the surface at a microscopic level, providing a bright, clean finish, ideal for medical and food processing applications. Bead blasting creates a uniform matte finish by propelling fine abrasive materials, commonly used for aesthetic purposes. Powder coating adds a protective layer of paint, increasing corrosion resistance and providing color options.

Anodizing (although rare for stainless steel) can enhance surface hardness and appearance.

Chemical blackening creates a dark finish that improves wear resistance and minimizes reflection.

Brushing offers a satin or hairline finish, popular for decorative applications in consumer goods and architecture.

These surface treatments ensure that stainless steel parts meet both functional and visual requirements across various industries.

Types of Stainless Steel Machining

Types of stainless steel machining include CNC milling, turning, precision grinding, drilling, laser cutting, welding, sheet metal forming, and EDM, each serving specific industrial needs.

| Machining Type | Process Description | Applications |

|---|---|---|

| CNC Milling | Removes material using rotating cutting tools to create complex shapes and precision parts. | Automotive parts, medical instruments, aerospace components. |

| CNC Turning | Lathe rotates the workpiece while a cutting tool shapes it. | Shafts, bushings, valves, fasteners, industrial fittings. |

| Precision Grinding | Achieves smooth surface finishes and tight tolerances using abrasive wheels. | Surgical tools, food processing equipment, optical devices. |

| Drilling and Tapping | Creates holes and threading them for screws and bolts. | Engine components, pressure vessels, mounting fixtures. |

| Laser Cutting | Uses high-powered lasers to cut stainless steel with precision. | Custom panels, decorative pieces, enclosures. |

| Welding and Fabrication | Joins parts through welding to ensure structural integrity. | Structural frameworks, storage tanks, piping systems. |

| Sheet Metal Forming | Involves cutting, bending, and assembling stainless steel sheets. | Electronic enclosures, kitchen appliances, medical cabinets. |

| Electrical Discharge Machining (EDM) | Uses electrical discharges to machine hard-to-reach areas. | Intricate molds and dies used in plastic injection molding. |

Common Applications of Stainless Steel CNC Machining

Stainless steel CNC machining is widely used in medical devices, aerospace components, food processing equipment, automotive parts, and oil & gas systems. It also supports applications in electronics, construction, and marine industries, offering high precision, durability, and corrosion resistance for critical components across various sectors.

| Industry | Applications |

|---|---|

| Medical Devices | Surgical instruments, implants, and dental tools. |

| Aerospace Components | Engine parts, fasteners, and structural elements. |

| Food Processing Equipment | Sanitary fittings, mixers, and containers. |

| Automotive Industry | Exhaust systems, trims, and engine components. |

| Oil & Gas Industry | High-pressure valves, pipes, and fittings. |

| Electronics | Enclosures, connectors, and heat sinks. |

| Construction | Structural elements, railings, and panels. |

| Marine Industry | Propeller shafts, marine hardware, and pumps. |

How to Evaluate the Quality of Stainless Steel Parts?

Evaluating stainless steel parts begins with ensuring dimensional accuracy. Precise measurements are essential, and parts must meet specified tolerances to ensure they fit seamlessly into assemblies. RALLY’s machining ensures tight tolerances of ±0.01mm for high-precision components.

In addition to dimensions, surface finish and structural integrity are critical. A uniform surface treatment, such as polishing or passivation, improves both the appearance and corrosion resistance of the parts. Structural integrity ensures the part is free from defects like warping, cracks, or other deformations that could compromise its performance.

At RALLY, we employ a comprehensive quality control process. Every part undergoes 100% inspection before shipment, ensuring not only precise dimensions but also proper surface finish and mechanical strength. Our ISO-certified processes guarantee parts meet both functional and aesthetic requirements.

Tolerances and Precision Control in Stainless Steel Machining

In stainless steel CNC machining, advanced equipment and processes, such as multi-axis CNC machines and precision grinding, are used to meet strict dimensional requirements.

The typical tolerances for stainless steel parts depend on the complexity and size of the part but generally range between ±0.005 mm to ±0.02 mm.

For critical applications, such as aerospace or medical components, tolerances as tight as ±0.001 mm may be achieved.

Precision control involves quality checks throughout the machining process, including in-process inspections, coordinate measuring machines (CMM), and final product testing.

By maintaining these stringent standards, manufacturers ensure the performance and reliability of stainless steel components across industries.

Why Choose RALLY for Stainless Steel Machining?

Customization Based on Your Needs:

- RALLY offers tailored solutions to meet precise technical requirements, whether for prototypes, small-batch orders, or mass production.

Fast Delivery with Global Shipping:

- Our optimized production workflow ensures quick turnaround times, delivering to markets like the USA, Canada, Europe, and Australia efficiently.

Industry Expertise Across Multiple Sectors:

- RALLY supports industries such as aerospace, medical devices, food processing, and automotive, meeting their exacting quality standards.

- With experience in precision machining, RALLY guarantees products that meet strict tolerances and surface finish requirements.

Comprehensive Support from Start to Finish:

- We provide technical consultations, design optimization assistance, and post-production services to ensure every project’s success.

Work with RALLY for Stainless Steel Machining

Request a quote for new project today! No minimum order quantity and free samples available!