Are you a production engineer, purchasing manager, or project manager looking for high-quality aluminum turning services? This guide is tailored for professionals in industries like aerospace, medical devices, automotive, and consumer electronics. We will explore the essentials of turning aluminum parts, advanced techniques, troubleshooting tips, and how to select the best service provider. Discover why RALLY is your ideal partner for precision-engineered aluminum components, ensuring your projects meet the highest standards of quality and efficiency.

Key Takeaways:

- Understand the basics and benefits of turning aluminum parts.

- Learn advanced turning techniques and best practices.

- Discover solutions to common turning issues.

- Explore case studies across various industries.

- Get tips for selecting a reliable aluminum turning service provider.

- Learn why RALLY is the ideal partner for your aluminum turning needs.

1. Introduction

1.1 Overview of Turning in CNC Machining

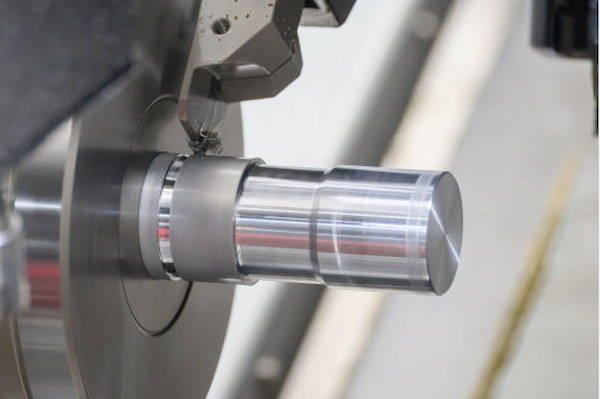

Turning is a precision machining process where a cutting tool moves in a linear path while the workpiece rotates. This process is essential in creating cylindrical parts with high accuracy and smooth finishes. In CNC machining, turning offers enhanced precision, repeatability, and efficiency, making it a preferred method for manufacturing aluminum components.

1.2 Importance of Aluminum in Manufacturing

Aluminum is highly valued in manufacturing due to its lightweight nature, corrosion resistance, and excellent machinability. It is widely used across various industries, including aerospace, automotive, medical devices, and consumer electronics. Its ability to be easily shaped and formed without compromising strength makes it ideal for creating complex and precise parts.

2. Basics of Turning Aluminum Parts

2.1 What is Turning?

Turning is a machining process that involves rotating a workpiece and cutting it with a fixed tool. It is usually performed on a lathe, which can be manually operated or computer numerical control (CNC) operated. In turning, the workpiece is rotated while the tool moves along the axis of the workpiece to remove material and form the desired shape.

2.2 Why Choose Aluminum for Turning?

Material Properties and Benefits: Aluminum is a preferred material for turning due to its favorable properties.

1. Ease of machining: Aluminum is a relatively soft metal that is easier to cut and shape than steel. This allows aluminum materials to be cut quickly and easily by machine tools, making machining efficient.

2. Cost-effective: Although aluminum is not the least expensive to produce, it is an affordable option relative to its advantages. This makes aluminum an ideal material for many manufacturing applications.

3. Corrosion Resistance: Aluminum rapidly forms a protective layer of aluminum oxide on its surface, increasing its corrosion resistance. This allows aluminum parts to remain in good condition in harsh environments.

4. Variety of surface treatment options: Aluminum can be subjected to a variety of surface treatments, such as anodic oxidation, to obtain different colors and surface characteristics. This provides more options for product design.

5. Precision machining capability: Through CNC machining, high precision machining of aluminum can be achieved to meet the requirements of precision parts.

2.3 Common Applications of Turned Aluminum Parts

Applications: Turned aluminum parts are used in a variety of industries and applications, including:

- Aerospace: Components such as landing gear, aircraft fittings, and structural parts.

- Automotive: Engine components, transmission parts, and suspension systems.

- Medical Devices: Surgical instruments, diagnostic equipment, and prosthetics.

- Consumer Electronics: Housings, connectors, and heat sinks.

- Industrial Machinery: Shafts, rollers, and fasteners.

- Sporting Goods: Bicycle frames, golf clubs, and other high-performance equipment.

3. Preparing for Aluminum Fabrication

3.1 Preparing Aluminum for Turning

Material Selection and Pre-Treatment:

Selecting the right aluminum alloy is crucial for optimal results. Common alloys like 6061 and 7075 offer excellent machinability and strength. Pre-treatment processes such as annealing can enhance the material’s machinability and reduce tool wear.

3.2 Choosing the Right Tools and Equipment

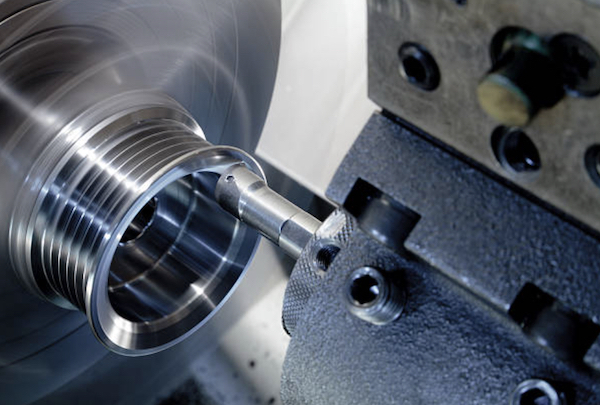

Types of Lathes and Cutting Tools:

For turning aluminum, high-speed steel (HSS) and carbide tools are commonly used. CNC lathes provide the precision and repeatability needed for complex parts. Considerations include the lathe’s size, power, and control system.

3.3 Setting Up the Machine

Machine Calibration and Setup Tips:

Proper machine setup is essential for achieving accurate and consistent results. Calibrate the lathe to ensure all components are aligned correctly. Use precision instruments to check the alignment of the spindle, tailstock, and tool holder.

Optimizing Cutting Parameters

Speed, Feed, and Depth of Cut: Determining the optimal cutting parameters involves balancing speed, feed rate, and depth of cut. Higher speeds can improve surface finish but may increase tool wear. Adjust the feed rate to achieve the desired surface quality and material removal rate.

Coolant and Lubrication

Importance and Types of Coolants: Using the right coolant is vital to managing heat generation and improving tool life. Water-soluble coolants are commonly used in aluminum turning due to their excellent cooling properties and ability to flush away chips. Ensure adequate coolant flow to the cutting zone to prevent overheating and tool damage.

Get Your CNC Parts Into Production Today

Your Global Partner for Quality CNC Machining Services in China!

4. Major Aluminum Fabrication Processes

4.1 High-Speed Turning

High-speed turning involves machining at significantly higher spindle speeds and feed rates compared to conventional turning. This method enhances productivity and reduces machining time. Benefits include improved surface finish, reduced tool wear, and increased material removal rates. High-speed turning is particularly advantageous for aluminum due to its excellent machinability and heat dissipation properties.

4.2 Hard Turning

Hard turning is the process of machining hardened materials (typically above 45 HRC) using single-point cutting tools. This method can replace grinding processes, providing cost savings and flexibility. Hard turning of aluminum is less common but can be applied to certain aluminum alloys that require enhanced wear resistance and strength.

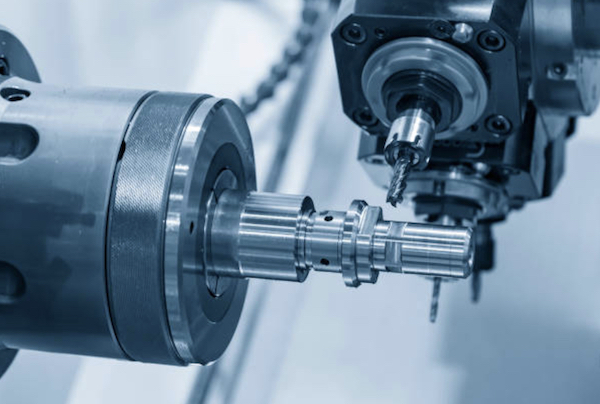

4.3 Multi-Axis Turning

Multi-axis turning involves the use of lathes with multiple axes of motion (e.g., X, Y, Z, and C axes) to perform complex machining operations in a single setup. This method increases machining flexibility, reduces setup times, and improves accuracy by minimizing part handling.

Applications: Multi-axis turning is ideal for creating complex geometries and intricate designs. It is widely used in the aerospace, medical device, and electronics industries for manufacturing components such as turbine blades, orthopedic implants, and intricate housings.

4.4 Turning with CNC Automation

CNC automation in turning involves the use of computer numerical control (CNC) systems to automate the machining process. This method enhances precision, repeatability, and efficiency. CNC automation allows for the production of complex parts with minimal human intervention, reducing the risk of errors and increasing productivity.

5. Case Studies and Examples

5.1 Successful Projects in Aerospace

Project Description: A leading aerospace company required precision-turned aluminum components for their new aircraft model. The parts needed to meet stringent safety and performance standards.

RALLY’s Role: RALLY provided high-speed turning services to manufacture lightweight, corrosion-resistant components with exceptional accuracy. The project involved tight tolerances and complex geometries, which RALLY successfully delivered on time and within budget.

Outcome: The aerospace company reported improved performance and reliability of their aircraft, attributing the success to the high-quality components supplied by RALLY.

5.2 Medical Device Manufacturing

Project Description: A medical device manufacturer needed custom-turned aluminum parts for surgical instruments. The parts required a high level of precision and biocompatibility.

RALLY’s Role: RALLY utilized multi-axis turning to create intricate and precise components, ensuring they met the medical industry’s strict regulatory standards. The project also involved surface treatments to enhance biocompatibility and corrosion resistance.

Outcome: The medical device manufacturer successfully launched their new line of surgical instruments, receiving positive feedback from medical professionals for the quality and performance of the tools.

5.3 Automotive Industry Applications

Project Description: An automotive company sought durable and lightweight turned aluminum parts for their high-performance vehicles. The parts needed to withstand extreme conditions and provide optimal performance.

RALLY’s Role: RALLY employed hard turning techniques to manufacture robust components with excellent wear resistance. The parts were designed to meet the automotive industry’s demanding specifications, including high strength and precision.

Outcome: The automotive company reported enhanced vehicle performance and durability, leading to increased customer satisfaction and market success.

5.4 Custom Consumer Electronics Parts

Project Description: A consumer electronics company required custom-turned aluminum housings for their new product line. The parts needed to be aesthetically pleasing and functional.

RALLY’s Role: RALLY used CNC automation and high-speed turning to produce sleek and precise housings. The project also included custom finishes to enhance the visual appeal of the products.

Outcome: The consumer electronics company successfully launched their new product

6. Why Choose RALLY as Your Aluminum Turning Partner

Long Existence and Large Size of RALLY:

With years of experience and a large operational scale, RALLY has established itself as a reliable and reputable provider in the industry.

Strong R&D Capability:

RALLY’s dedicated research and development team continuously innovates to improve processes and products, ensuring cutting-edge solutions for your projects.

Extensive Experience in Europe and USA Markets:

RALLY has a proven track record of successfully serving clients in Europe and the USA, understanding their specific needs and regulatory requirements.

Customization Based on Technical Drawings:

RALLY offers customization services based on your technical drawings, ensuring the final products meet your exact specifications.

No Minimum Order Quantity:

RALLY accommodates both small and large orders, providing flexibility to clients regardless of project size.

High Quality and Precision Standards:

RALLY adheres to stringent quality control measures, ensuring high precision and top-notch quality in every part produced.

Testimonials from Satisfied Clients:

Numerous clients have praised RALLY for their exceptional service, quality, and reliability. These testimonials highlight RALLY’s commitment to customer satisfaction.

Choosing RALLY as your aluminum turning partner ensures that your projects are handled with expertise, precision, and a commitment to excellence.

7. Conclusion

Turning aluminum parts is a critical process across various industries, requiring precision and expertise. This guide has provided insights into techniques, best practices, and advanced methods to help you achieve superior results. By partnering with RALLY, you gain access to a team with extensive experience, strong R&D capabilities, and a commitment to high quality and precision. Whether your project is large or small, RALLY can meet your specific needs with customized solutions and exceptional service.

Ready to take your aluminum turning projects to the next level? Contact RALLY today for a consultation or quote.

Work with RALLY for CNC Machining Parts

Request a quote for new project today! No minimum order quantity and free samples available!